Mimaki has enhanced its production-class Tiger 1800B digital textile printer family with new features and capabilities. The Tiger 1800B MkII offers an additional high-quality mode at 1200 dpi and several enhancements to improve quality, including reduction of banding and other printing defects.

Mimaki has enhanced its production-class Tiger 1800B digital textile printer family with new features and capabilities. The Tiger 1800B MkII offers an additional high-quality mode at 1200 dpi and several enhancements to improve quality, including reduction of banding and other printing defects.

“The conventional-to-digital transformation continues to heat up in textiles and apparel, and Mimaki, an early mover in this space, is dedicated to bringing affordable, industry-leading solutions to this segment,” said Bert Benckhuysen, Product Manager EMEA at Mimaki Europe. “The Tiger 1800B MkII printers, available in two models for direct to textile and heat transfer sublimation, are just another example of this strategy in action. And our strategy goes beyond simply providing outstanding printers – especially in an emerging market such as this, it is critical to be a total solutions provider. To that end, we are also making available a new range of pre-treatment and post-treatment machines, and we are working towards the development of Internet of Things for Textiles and Apparel market.”

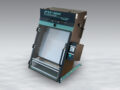

Mimaki Tiger-1800B MkII

Mimaki Tiger-1800B MkII

The Mimaki Tiger-1800B MkII prints at up to 385 square meters per hour and can cover a wide production range, from sample making to small to medium print runs. An additional 1200 dpi print mode is available for enhanced print quality.

A set of Mimaki’s Core Technologies has also been added to the machine. Mimaki Advanced Pass System (MAPS) minimizes banding and colour shifting by spreading the edge of the pass, making the boundary area a gradation, resulting in a smoother printed image. Mimaki’s Nozzle Checking Unit (NCU) and Nozzle Recovery System (NRS) are also incorporated in these new printers, enabling continuous high quality printing even if nozzle errors occur.

Mimaki is also making available an extensive line-up of optional devices to meet just about every fabric and transfer paper printing need. This includes a feeding unit for roll media equipped with a centering device and tension bar; a jumbo roll unit to enable printing of long-length roll fabric or heat transfer paper; and drying and winding or pleating options for printed fabrics.

Mimaki Vision Jet-X

At FESPA 2018, Tiger-1800B MkII has been shown in combination with the jumbo roll of Mimaki Vision Jet-X sublimation transfer paper. Available in 1620 and 1830 mm widths, the Mimaki Vision Jet-X is lightweight (57g/m2), but suitable for producing almost everything from sports apparel, flags and banners requiring a high density of ink deposition to fashion and home fabrics with less ink coverage. It yields stable paper feeding and printing, preventing shrinkage and mis-registration of paper.