Kornit Digital was present at SGIA Expo. They showed a variety of systems and solutions for both direct-to-garment and direct-to-fabric printing including the Allegro direct-to-fabric printer that for the time used neon inks, enabling new and creative applications.

Kornit Digital was present at SGIA Expo. They showed a variety of systems and solutions for both direct-to-garment and direct-to-fabric printing including the Allegro direct-to-fabric printer that for the time used neon inks, enabling new and creative applications.

Kornit set up a garment decoration factory where visitors could design their individual shirts and had them produced live during the show. This solution was based on their collaboration with Custom Gateway. In addition, visitors experienced live demos of the heavy-duty direct-to-garment printing system Avalanche 1000 R-Series and the Kornit Vulcan, a digital alternative to screen printing. The Vulcan won SGIA’s 2017 Product of the Year Award, in the category “Direct-to-garment printers (Color Shirt – Not White)”.

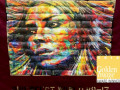

Allegro’s new colors

At SGIA Expo Allegro’s new colors were shown. The new neon inks – pink and yellow – extend the Allegro’s color gamut by brighter colors and new shades while ensuring excellent color fastness. It helps Allegro users to penetrate new market segments and to increase system utilization. Existing Allegro customers can move to the new inks which are field upgradeable.

The Allegro eliminates the need for pre and post-treatment for multiple fabrics, all within a seven meters integrated production line. The system is 70.8” / 1.80m wide, and is based on Kornit’s NeoPigment printing technology, which supports high quality printing on both natural, man-made and synthetic fabrics. The Kornit Allegro can be located anywhere without environmental constraints, designed to support ultra-short up to medium-length runs.

Avalanche 1000 R-Series

The Avalanche 1000 R-Series was also on display. Designed for the mass production of garments it has dual pallet industrial production capability, and is a very robust platform designed for heavy duty use. Thanks to a patented double bridge architecture, the white and the color print phases happen in parallel for dark garment efficiency. It prints up to 220 light and 160 dark garments per hour. The Avalanche 1000 R-Series can be used all day, every day and for all volumes. It is equipped with a recirculating ink system. This technology optimizes print quality, reliability and ink efficiency.

Vulcan

SGIA’s 2017 Product of the Year Award Kornit’s Vulcan was also at the show. It is a digital alternative to screen printing machines. This heavy-duty production system is targeted to screen printers producing collections and short runs for retailers and promotional purposes. The Vulcan offers low cost per print for run lengths between 50 and 500 garments. Unlike Kornit’s traditional direct-to-garment printing systems, the Vulcan sports a conveyor system for the printed pallets with pre-treatment, white and CMYKRG printing happening in sequence. The Vulcan prints up to 250 garments per hour, both on dark and light garments.

Custom Gateway partnership

As part of Kornit’s ongoing effort to surround its production technology with an ecosystem of workflow and mass customization solutions, the company has initiated a collaboration with Custom Gateway, a large solution provider for advanced web-to-print businesses enabling personalized, customized and print-on-demand products with a full production workflow solution. The outcome of this partnership is an end-to-end web-to-print and fulfillment solution, combining Kornit’s one-step printing process with a complete workflow including a web shop, order management and automated production.